In-process inspection of Hot fused down filled vest

2021-01-19 11:12

We keep high quality sense in mind in our production line.

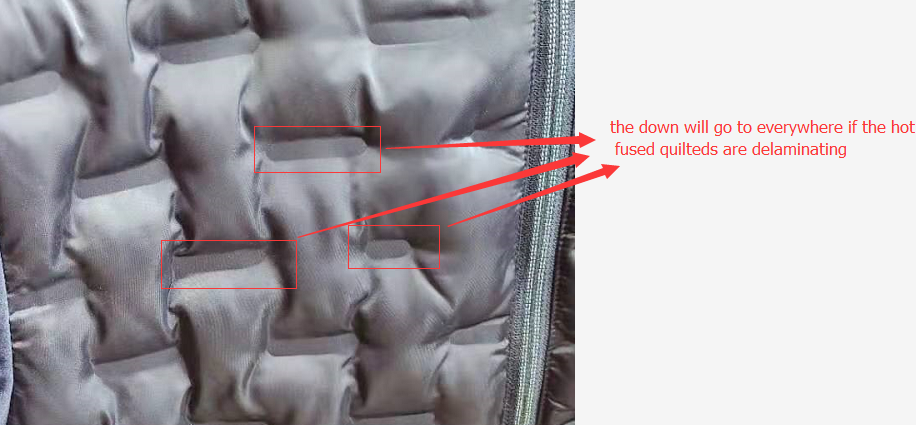

This project is a hot fused down filled vest, we are checking some points which are easy to make mistakes, such as if the hot fused quilted is fix strongly enough, for a hot fused quilted style garment, it is the most important to keep hot fused quilted fix strongly to avoid delaminating of hot fused quilted, as below:

Under daily situation, we need to do a laundry when the vest is after wearing, which makes a high requirement for the fixing because the quilteds were made by hot-fused instead of stitching. We should guaranteed all of hot fused quilteds were fix strongly before our consumers receiving it.

The second stage we need to check is the workmanship of vest, a good shape and pattern is necessary based on artwork, which makes vest looking nice and let people feeling comfortable when they are wearing. Normally, the shape or pattern will not make mistake because we had check shape and pattern through proto samples/ SMS/PPS/shipping samples.

The third stage we will check all of trims, such as the zippers, badge labels, prints, press buttons, bindings, drawstring and stoppers.

The third party also need to check the packing materials.

We welcome our clients to do a in process inspection for our products, it is a good way to know each other through this.

Get the latest price? We'll respond as soon as possible(within 12 hours)